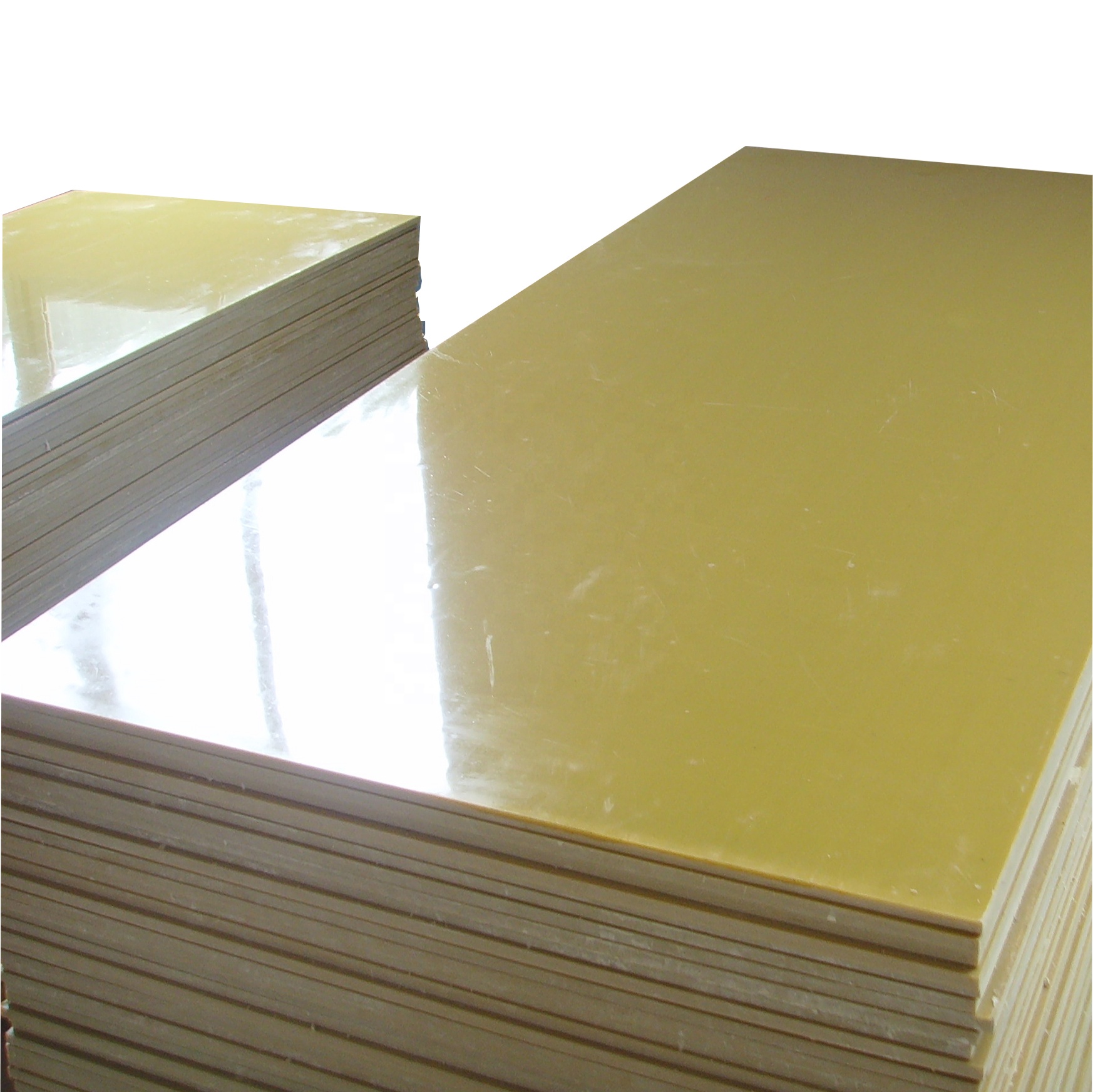

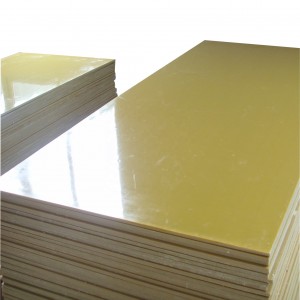

Shiinaha phenolic resin sheet 3240

Sharaxaada Alaabta

3240 Epoxy phenolic galaas fiber la dahaadhay xaashida (aan buuxin):Alaabtani waa badeeco la dahaadhay oo ka samaysan koronto ujeedo leh alkali-free maro galaas maro leh epoxy phenolic resin by kulul pressing.The thermostablity waa darajada B.It waxa uu leeyahay sifooyin farsamo iyo dielectrical wanaagsan,

Lagu dabaqi karo makaanikada, korontada, elektiroonigga, korontada iyo meelaha kale. Waxa kale oo loo isticmaalaa habaynta qaybaha dahaadhka, waxaana lagu farsameeyaa dhammaan noocyada kala duwan ee qaybaha dahaadhka iyo qalabka dahaadhida qaybaha dhismaha, kuwaas oo loo isticmaali karo xaaladaha deegaanka qoyan iyo saliidda beddelka.

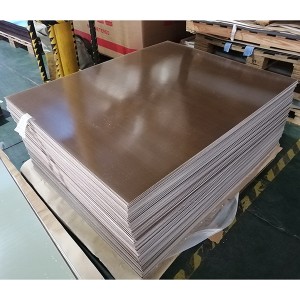

3240 Epoxy phenolic galaas fibre la dahaadhay xaashida (oo leh buuxin):Alaabtani waa badeeco la dahaadhay oo ka samaysan koronto ujeedo leh alkali-free maro galaas maro leh epoxy phenolic resin iyo buuxinta adigoo riixaya kulul. Wixii macluumaad dheeraad ah, fadlan si naxariis leh la tasho qofkayaga wax iibinaya.

U Hogaansanaanta Heerarka

Iyada oo la raacayo GB/T 1303.4-2009 resin thermosetting koronto laminates adag warshadaha - Qaybta 4: epoxy resin laminates adag, IEC 60893-3-2-2011 walxaha dahaarka - korantada resin warshad adag laminates - Qaybta 3-2 ee sheyga gaarka ah EPGC201.

Astaamaha

1.Good farsamooyinka farsamada;

2.Good guryaha dielectrical;

3.Cabitaanka qoyaanka, ku habboon hoos

deegaanka qoyan iyo saliid transformer.

4.Good machinability guryaha

5.Cabsiga heerkulka: darajada B

Codsiga

1) Loo isticmaalo shuruudaha waxqabadka farsamada ee matoor sare, qalabka korantada iyo qaybaha dhismaha ee dahaarka

2) ICT, ITE xeer nidaaminta qaybaha dahaarka, qalabka tijaabada, caag caag caag caag ah ee qaybaha dahaarka.

3) saxan go'an, alwaax caaryada, countertops saxan shiidi, mashiinada baakadaha, shanlada, iwm

Tusmada Waxqabadka Ugu Weyn

| MAYA | ITEM | CUTUB | QIIMAHA INDEX | ||

| 1 | Cufnaanta | g/cm³ | 1.8-2.0 | ||

| 2 | Heerka nuugista biyaha | % | ≤0.5 | ||

| 3 | Xoog foorarsi toosan | MPa | ≥340 | ||

| 4 | Xoog cadaadis toosan | MPa | ≥350 | ||

| 5 | Xooga isbarbar socda (nooca faraqa u eg) | KJ/m² | ≥33 | ||

| 6 | Xooga isbarbar socda (habka iftiinka cantilever) | KJ/m² | ≥34 | ||

| 7 | Xoog xiirid barbar socda | Mpa | ≥30 | ||

| 8 | Xoog xajin | MPa | ≥200 | ||

| 9 | Awood koronto oo toosan (saliid 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 10 | Danab burburka isbarbar socda (ku jira saliidda 90 ℃ ± 2 ℃) | KV | ≥35 | ||

| 11 | Qodobka kala-baxa Dielectric (50Hz) | - | ≤0.04 | ||

| 12 | Iska caabinta dahaarka | Caadi ah | Ω | ≥5.0×1012 | |

| Ka dib markii la qooyay 24 saacadood | ≥5.0×1010 | ||||