G12 Epoxy Fiberglass Laminated

Tilmaamaha Alaabta

Qalabka G12 waa daaweynta kiimikada korontada loogu talagalay alkali-free fiberglass laminates xoojiyay, bonded la resin.It sare TG epoxy awood sare hoos heerkulka caadiga ah, weli waxa uu leeyahay xoog farsamo xoog leh, guryaha korontada wanaagsan hoos deegaanka qalalan iyo qoyan, waxaa loo isticmaali karaa in deegaanka qoyan iyo transformer oil.It iska leh fasalka H wax dahaarka iska caabin kulaylka.

U hoggaansanaanta heerarka

Iyada oo la raacayo GB/T 1303.4-2009 resin thermosetting korantada laminates adag warshadaha - Qaybta 4: epoxy resin laminates adag, IEC 60893-3-2-2011 walxaha dahaarka - korantada xabagta resin warshadaha adag laminates - Qaybta 3-2 ee sheyga gaarka ah EPGC308.

Codsiga

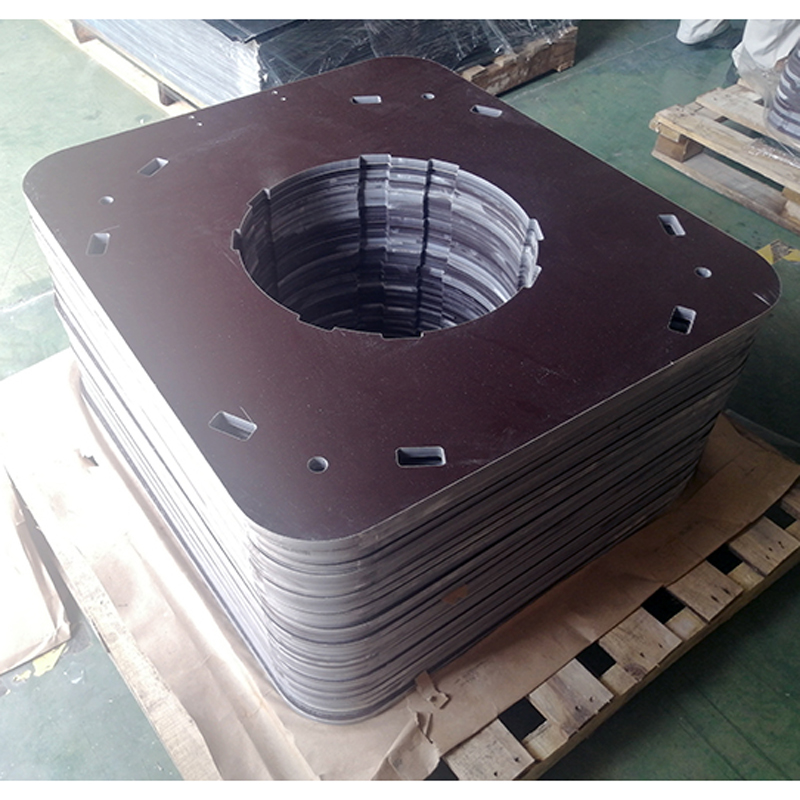

Ku habboon fasalka 180 (H) matoorada jiidashada, matoorada waaweyn sida godadka godadka iyo qalabka korantada ee dhamaadka-sare sida natiijooyinka kuleylka u adkaysta,

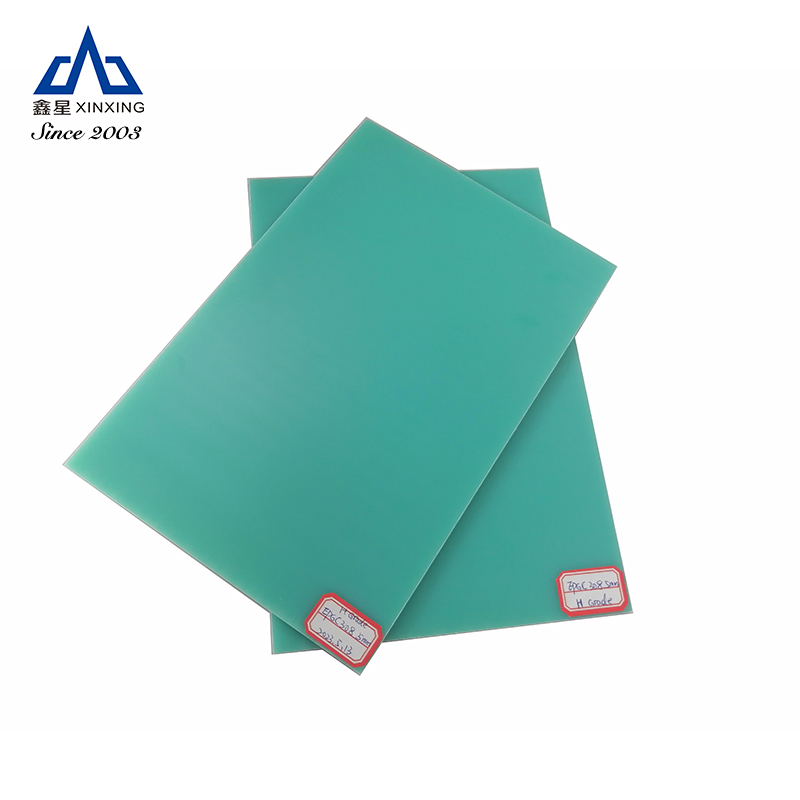

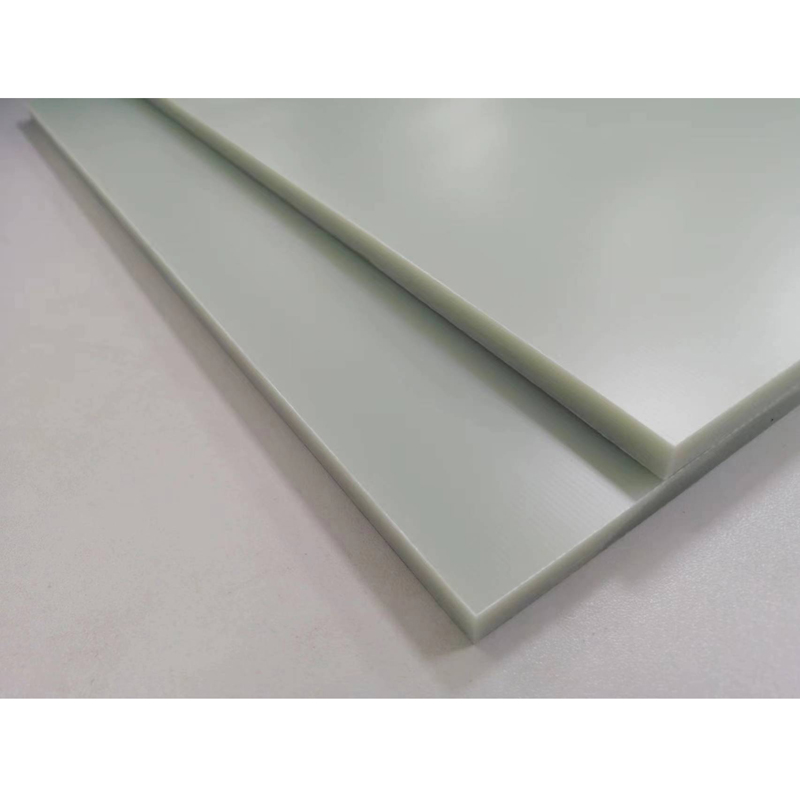

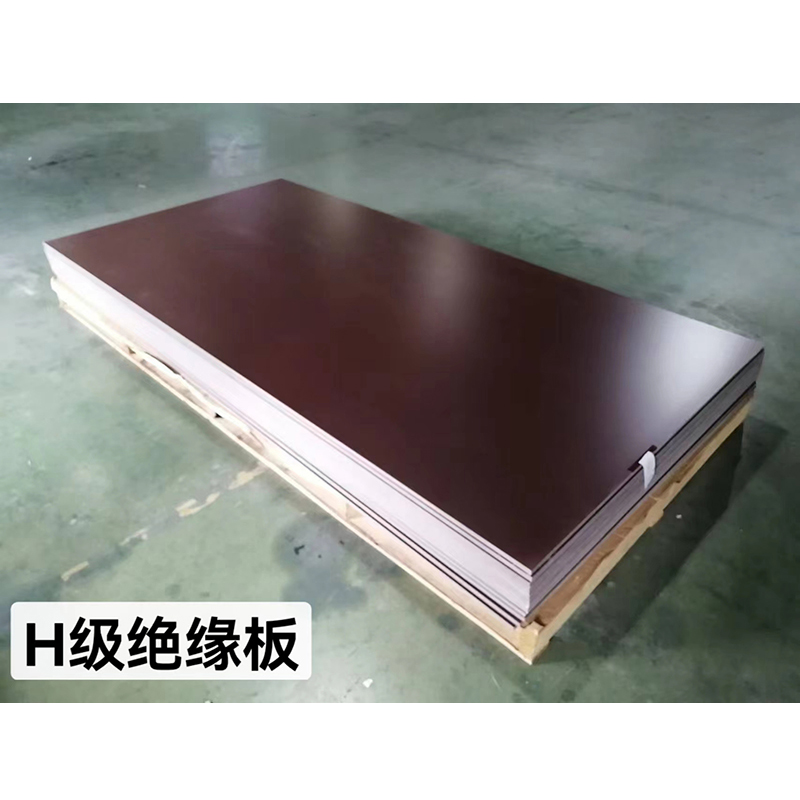

Sawirada alaabta

Taariikhda Farsamada ugu weyn (guji halkan si aad u soo dejiso warbixinta imtixaanka qolo saddexaad)

| Shayga | Hanti | Unug | Heerka caadiga ah | Qiimaha caadiga ah | Habka Imtixaanka |

| 1 | Xoog dabacsanaan ah oo siman ilaa lamination (MD,23℃±2℃) | MPa | ≥380 | 556 | GB/T 1303.2 |

| 2 | Xoog dabacsanaan ah oo siman ilaa lamination (MD,180℃±2℃) | MPa | ≥190 | 298 | |

| 3 | Xoog dabacsanaan ah oo siman ilaa lamination (MD,23℃±2℃) | MPa | _ | 24252 | |

| 4 | Awood saameyn leh oo la mid ah laminations (Notched, MD) | kJ/m2 | ≥37 | 111 | |

| 5 | Xoog xajin (MD) | MPa | ≥300 | 557 | |

| 6 | Xoog isku dhejisan oo ku siman lamination (23 ℃ ± 2 ℃) | MPa | ≥380 | 640 | |

| 7 | Xoog cadaadis leh oo siman oo ku dheggan lamination (180 ℃ ± 2 ℃) | MPa | ≥190 | 378 | |

| 8 | Awood koronto oo siman oo ku xiran laminations (90 ℃ ± 2 ℃ 25 # saliid transformer, 20s tallaabo tallaabo tallaabo ah, Φ25mm / Φ75mm electrode cylindrical) | kV/mm | ≥14.2 | 19.2 | |

| 9 | Korantada jebintu waxay la mid tahay laminations (90 ℃ ± 2℃ in 25 # saliid transformer, 20s tallaabo tallaabo tallaabo, Φ130mm / Φ130mm saxan electrode) | kV | ≥45 | >100 | |

| 10 | Ogolaanshaha Qaraabada (1 MHz) | _ | ≤5.5 | 5.20 | |

| 11 | Cunsurka kala-baxa Dielectric (1MHz) | _ | ≤0.04 | 0.0102 | |

| 12 | Iska caabbinta dahaarka ka dib dhexgalka biyaha (MD, taper pin electrodes, farqiga 25.0mm) | Ω | ≥5.0 x1010 | 2.6x1014 | |

| 13 | nuugista biyaha | mg | ≤22 | 18.00 |

|

| 14 | Cufnaanta | g/cm3 | 1.7-2.0 | 1.98 | |

| 15 | Tilmaanta heerkulka | ℃ | _ | 180℃ | |

| 16 | TG | ℃ | _ | 200℃±5℃ |

FAQ

Q1: Ma waxaad tahay shirkad ganacsi ama soo saaraha?

Waxaan nahay saaraha hormuudka ah ee korantada isku dhafan, Waxaan ku hawlanaa saaraha thermoset isku dhafan adag tan iyo 2003.Our awood waa 6000TONS / sanadkii.

Q2: Tusaalooyinka

Muunadodu waa bilaash, kaliya waxaad u baahan tahay inaad bixiso kharashka dhoofinta.

Q3: Sideed u dammaanad qaadaysaa tayada wax soo saarka ballaaran?

Dhanka muuqaalka, cabbirka iyo dhumucda: waxaanu samayn doonaa kormeer buuxa ka hor inta aan la xidhin.

Tayada waxqabadka: Waxaan isticmaalnaa qaacido go'an, oo waxay noqon doontaa kormeer muunad joogto ah, waxaan ku siin karnaa warbixinta baaritaanka alaabta ka hor inta aan la dhoofin.

Q4: Waqtiga keenista

Waxay kuxirantahay tirada dalabka

Q5: Xidhmada

Waxaan u isticmaali doonaa warqad farshaxanimo xirfad leh si aan ugu xirno pallet plywood.haddii aad leedahay shuruudo xirmo gaar ah, waxaan u baakadeynaa hadba baahidaada.

Q6: Lacag bixinta

TT, 30% T/T ka hor, dheelitirka ka hor shixnadda. Waxaan sidoo kale aqbalnaa L/C.