Fasalka F Halogen-free dab-demiska Epoxy fiber-ka daboolan

Sharaxaada Alaabta

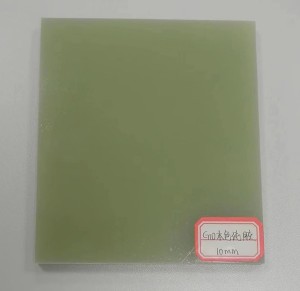

Alaabtan waxaa lagu sameeyay koronto-yaqaanka maro fiber galaas ah oo aan alkali ahayn sida wax lagu taageerayo, oo leh fosfooraska TG sare iyo nitrogen ololka resin epoxy sida binder iyada oo la adeegsanayo alaabada la riixay kulul, xoogga farsamada sare iyo waxqabadka gubashada hoose ee heerkulka caadiga ah, heerkul sare oo ka hooseeya 155 ℃ wali wuxuu leeyahay xoog farsamo oo xoog leh, guryaha korantada ee wanaagsan ee hoos yimaada gobolka qalalan iyo qoyan, waxaa loo isticmaali karaa jawi kuleyl ah F. material.Applicable in dhammaan noocyada motor, korontada, elektarooniga ah iyo beeraha kale, si ballaaran loo isticmaalo in motor, qalabka korontada sida qaybaha qaab-dhismeedka dahaarka, danab sare-marshad, beddelo danab sare (sida motor stator qalabka dahaaran labada daraf, saxan dhamaadka rotor gabal daaha rotor, wedge booska, guddiga terminal, iwm).

Astaamaha

1.Deganaansho koronto oo wanaagsan oo hoos yimaada huurka sare;

2.Awoodda farsamada sare ee heerkulka sare;

3.Cabitaanka qoyaanka;

4.Cabsiga kulaylka;

5.Cabsiga heerkulka: Fasalka F

6.Hogen-free iyo dab-demiska

U hoggaansanaanta heerarka

Iyadoo la raacayo GB/T 1303.4-2009 korantada heerkulbeegga korantada ee warshadaha adag laminates - Qaybta 4: epoxy resin hard laminates.

Muuqaalka: dusha sare waa inuu ahaadaa mid siman, oo aan lahayn xumbo, godadka iyo laalaabyada, laakiin cilladaha kale ee aan saameyn ku yeelan isticmaalka waa la ogol yahay, sida: xoqin, jeexid, wasakh iyo dhibco yar.

U hoggaansanaanta heerarka

Ku habboon dhammaan noocyada matoorka, qalabka korontada, qalabka elektarooniga ah iyo meelaha kale.

Tusmada Waxqabadka Ugu Weyn

| MAYA | ITEM | CUTUB | Qiimaha INDEX | ||

| 1 | Cufnaanta | g/cm³ | 1.8-2.0 | ||

| 2 | Heerka nuugista biyaha | % | ≤0.5 | ||

| 3 | Xoog foorarsi toosan | Caadi ah | MPa | ≥380 | |

| 155± 2℃ | ≥190 | ||||

| 4 | Xoog cadaadis | Toosan | MPa | ≥300 | |

| Barbar socda | ≥200 | ||||

| 5 | Xoogga saamaynta (nooca jilicsan) | Dhererka farqi malaha | KJ/m² | ≥147 | |

| 6 | Xoog isku xidhidh | N | ≥6800 | ||

| 7 | Xoog xajin | Jidka dheer | MPa | ≥300 | |

| Horizontal | ≥240 | ||||

| 8 | Awood koronto oo toosan (saliid 90 ℃ ± 2 ℃) | 1mm | KV/mm | ≥14.2 | |

| 2mm | ≥11.8 | ||||

| 3mm | ≥10.2 | ||||

| 9 | Danab burburka barbar socda (1 daqiiqo oo saliid ah 90 ℃ ± 2 ℃) | KV | ≥40 | ||

| 10 | Qodobka kala-baxa Dielectric (50Hz) | - | ≤0.04 | ||

| 11 | Iska caabinta dahaarka | Caadi ah | Ω | ≥1.0×1012 | |

| Ka dib markii la qooyay 24 saacadood | ≥1.0×1010 | ||||

| 12 | Gubashada (UL-94) | Heerka | V-0 | ||